Words & Photos from Dewi W.- Alternative Energy Cohort

Wednesday’s dreary morning was met by the excitement of another expedition day. We met with Mr. England, Mr. Donatelli, and Mr. Ingimundson explained to us that today’s task was focused on creating our very own wind turbines to put atop the science building.

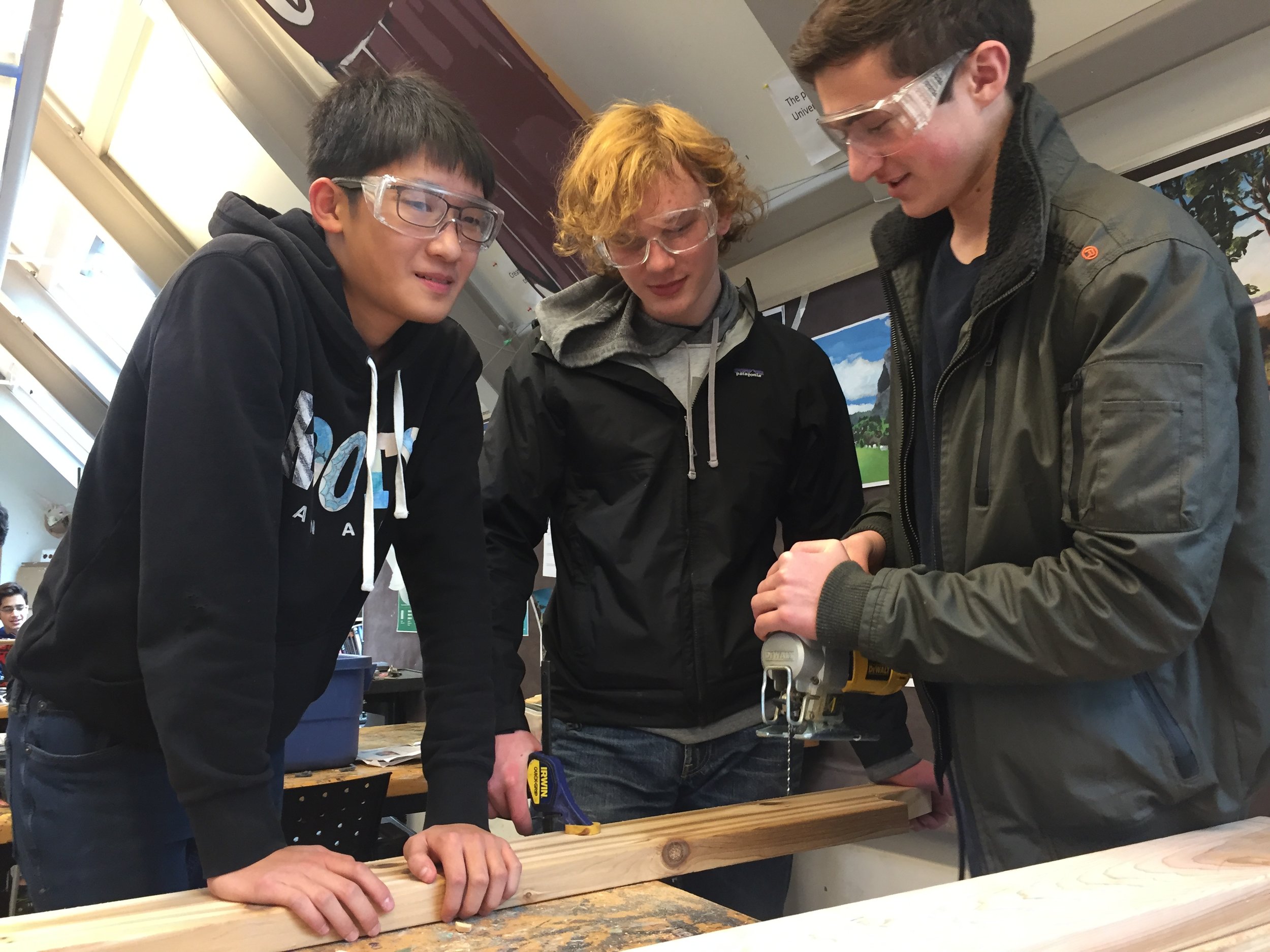

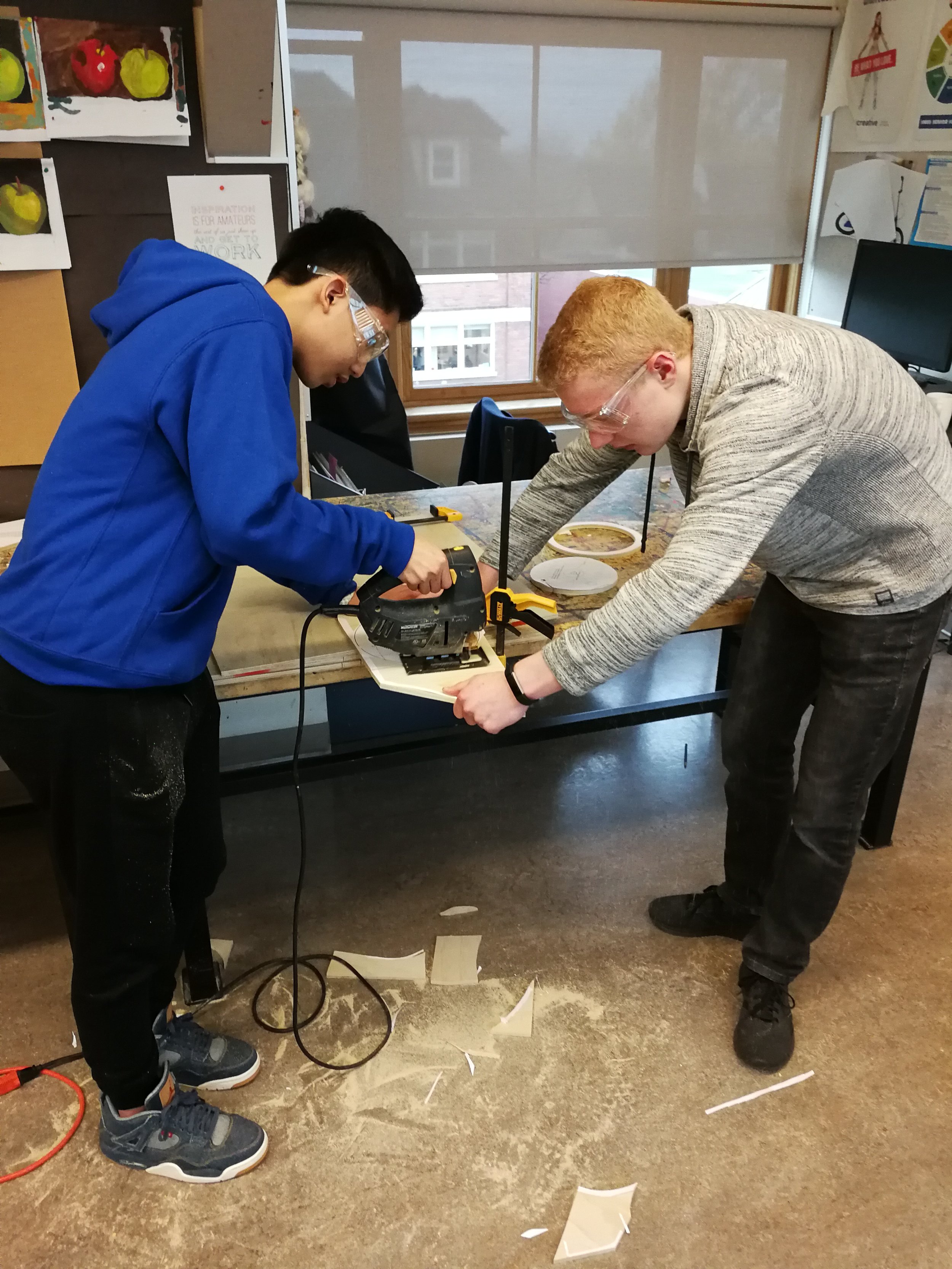

The work was split into three stations, one working with hard manual labour, another with more precise woodworking, and one creating energy alternators. As I said the first station was the hard manual labour, which was certainly an interesting wake-up call. The teachers simply put us next to a bench with wooden templates of what to build, a saw, a hammer, and a drill and told us to replicate everything four times. We got right down to it, happy to start off with an aggressive task. We copied the outline from the templates to the wood we were going to cut, grabbed a saw and sawed off. After we finished cutting the first plank of wood Mr. England brought us a jigsaw. We were all really hesitant and scared to use a jigsaw for the first time but cut after cut we got more confident and the work was immensely easier. Once we finished sawing we got on to drilling holes through the wood and screwing the bolts and nuts in to hold the pieces of wood together.

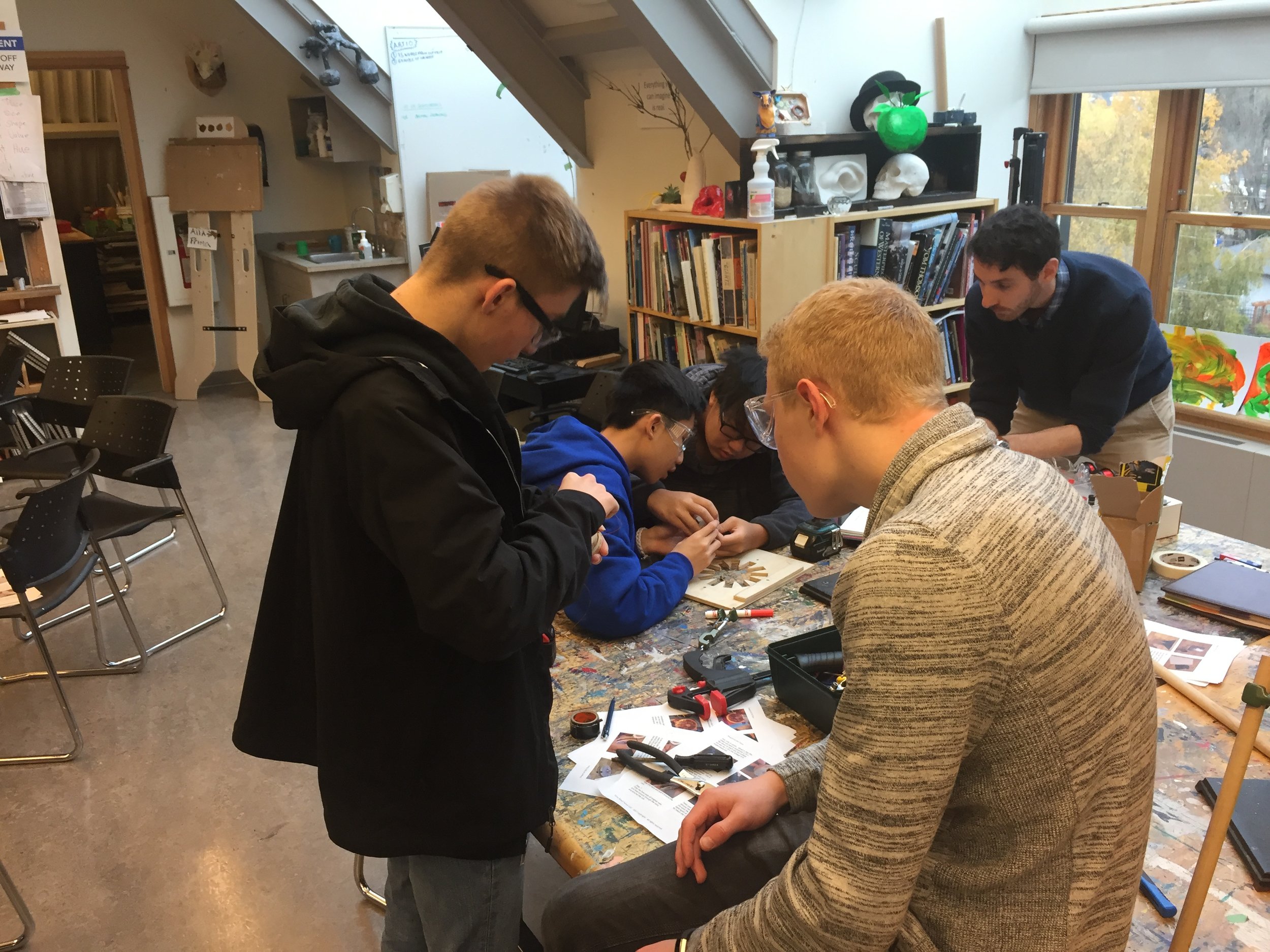

The rotation brought us to the second station which was focused on cutting out the heart of the wind turbine, the generator. Mr. I warned us that we had to be extremely careful in how we cut because it had to be extremely precise because the slightest imperfection in cutting out these pieces would result in an unbalanced disc, so a less efficient generator. We were using a jigsaw for this part too and it is a good thing that we had practice with it before because I feel like we would have cut extremely wavy instead of straight.

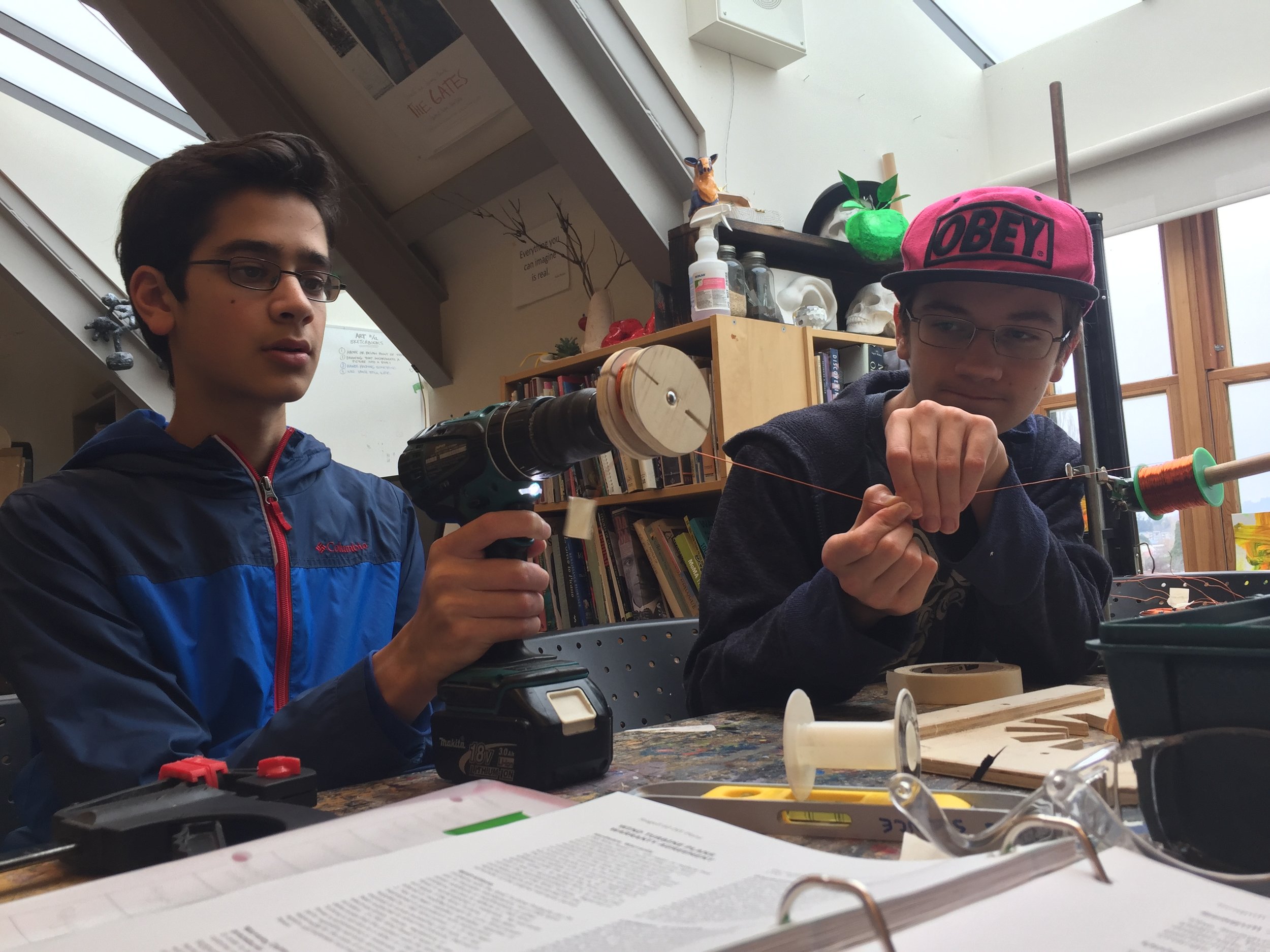

The third station finally gave us a bit of a break. We were supervised by Mr. Donatelli on how to coil up copper wire in a perfect way so that it would have the best repulsion on the magnets and so maximize efficiency. It was a painful job. We had the start of the coil stuck inside a wooden frame with a triangle shape on which we would coil up the wire so that it had the perfect shape. We attached that frame to a drill so we didn’t have to roll it up manually. Here comes the painful part: We had to count 250 turns of the coil and once we were done we took the coil out of the triangle and started again until we had 12 coiled up wires.

Apart from that our day was very fun and I particularly loved all the hands-on work on the wood and using the jigsaw. Having the chance to not only learn about alternative energy but actually working on it ourselves is the opportunity of a lifetime. I speak not only for myself but my fellow “cohort-classmates”.